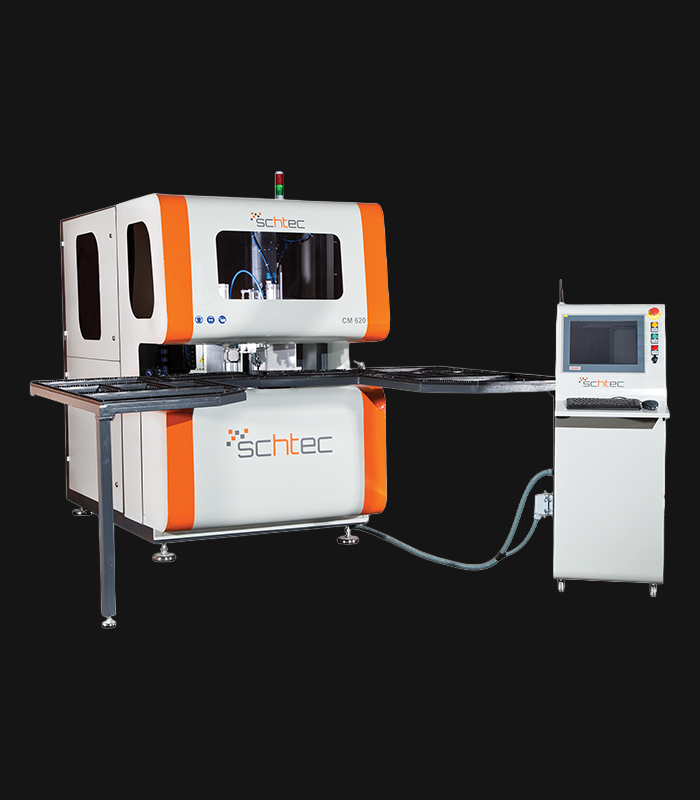

2 Eksenli ve 4 Eksenli Makineler: Üretim Hattınız İçin Hangisi Doğru?

When choosing a new corner cleaning machine, one of the first and most significant technical questions you'll face is: "Should I invest in a 2-axis or a 4-axis model?" The answer depends entirely on your production needs, product variety, and long-term business goals. This guide will clarify the key differences between these technologies to help you make the most informed decision for your facility.

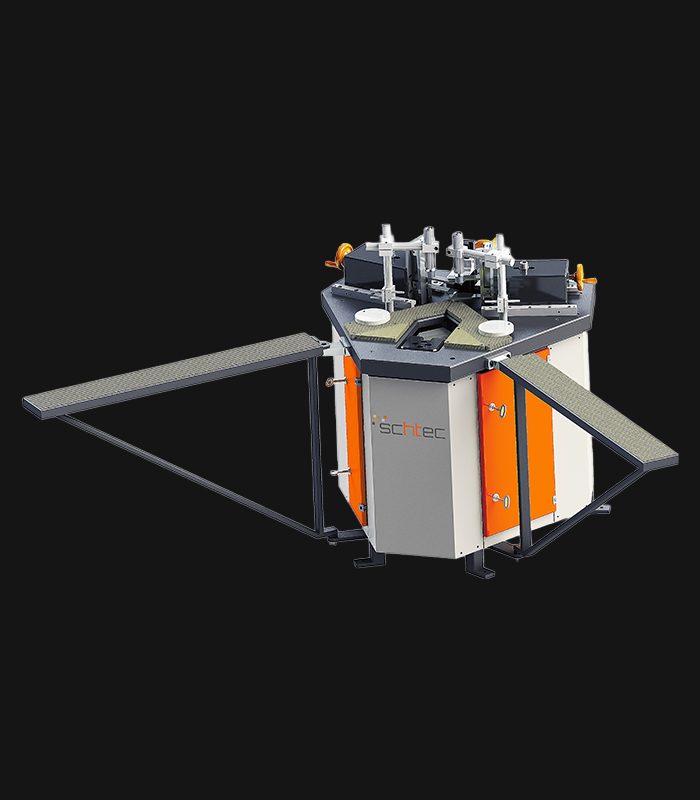

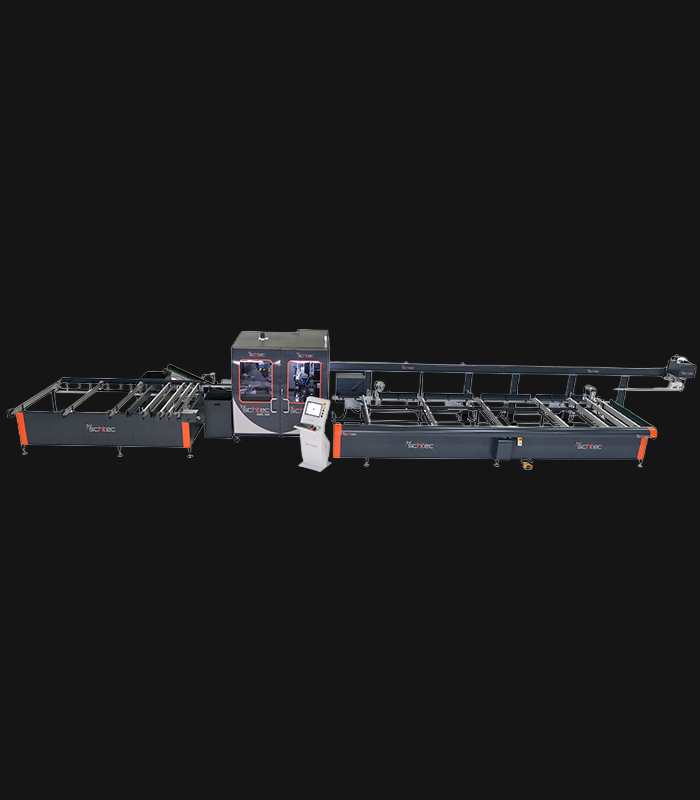

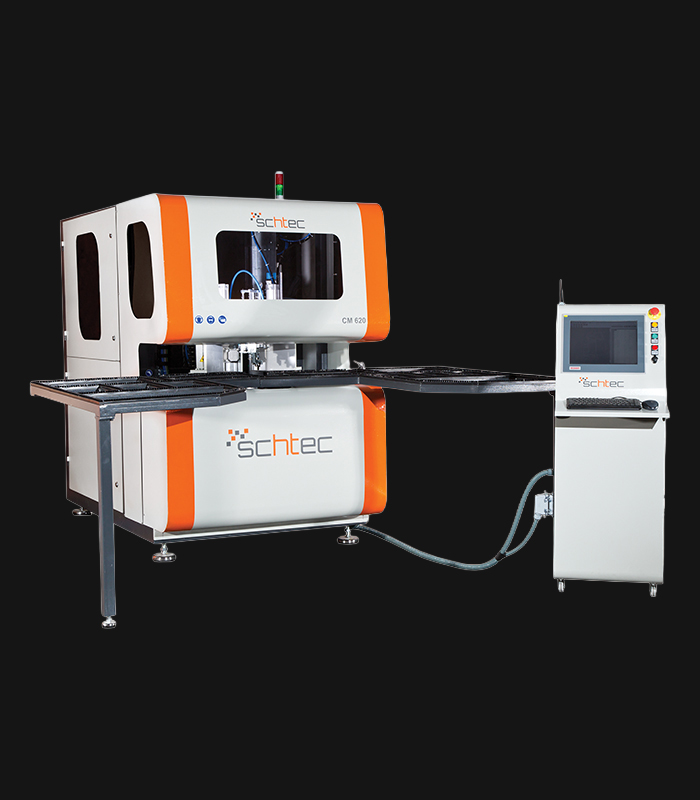

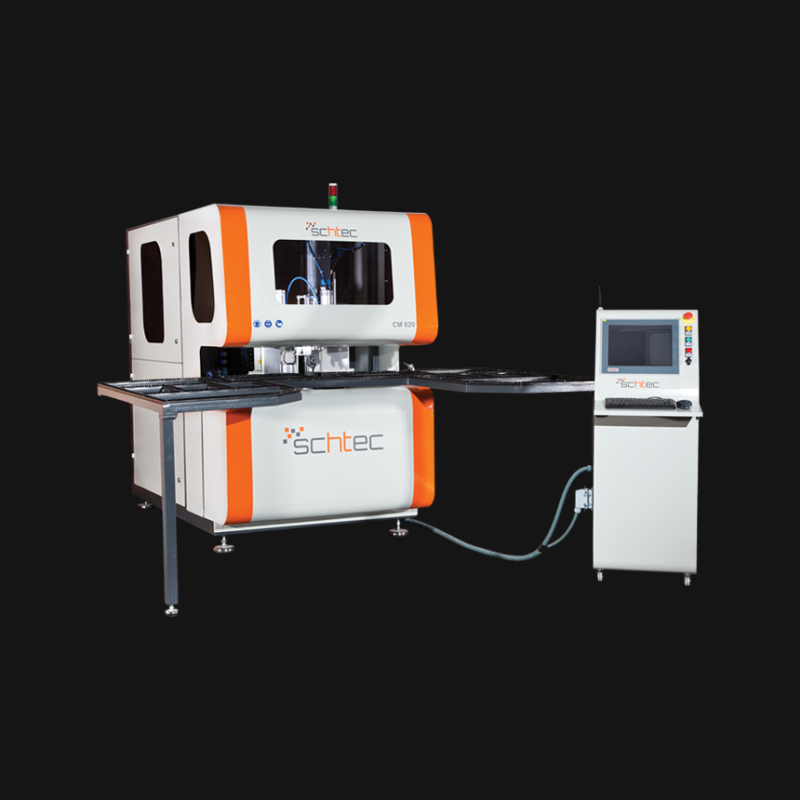

Understanding the 2-Axis Corner Cleaner: The Workhorse

A 2-axis corner cleaner is the industry standard and a true workhorse for many window and door manufacturers. As the name implies, it operates on two primary axes (typically X and Y) to perform its cleaning cycle.

What It Does: It is expertly designed to clean the top and bottom surfaces and the outer corner contour of standard 90-degree welded joints. It excels at processing high volumes of standard window and door profiles with incredible speed and reliability.

Who It's For: A 2-axis machine is the ideal, cost-effective choice for manufacturers who focus on producing a high volume of standard, rectangular frames. If your production consists of a limited range of simple profiles, a 2-axis machine will deliver exceptional efficiency and a rapid return on investment.

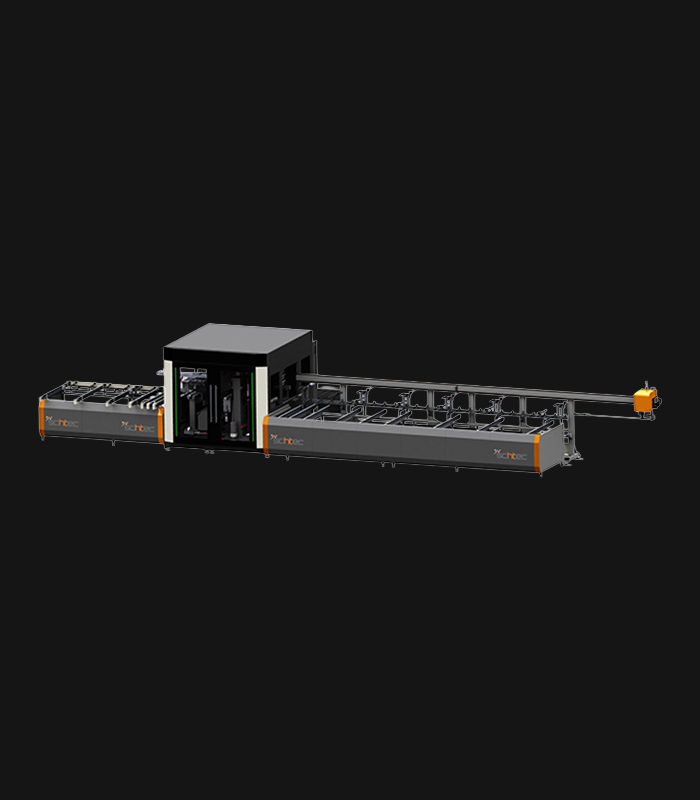

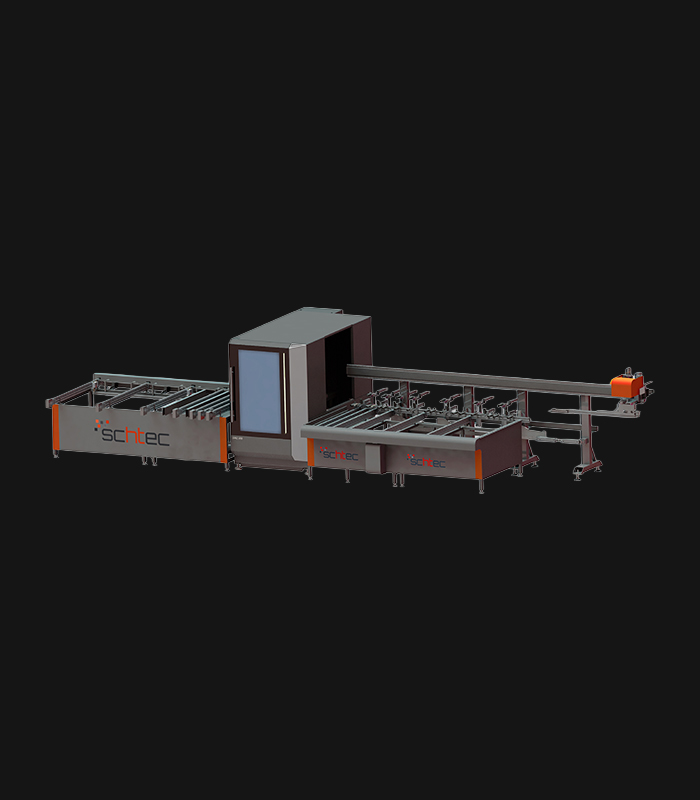

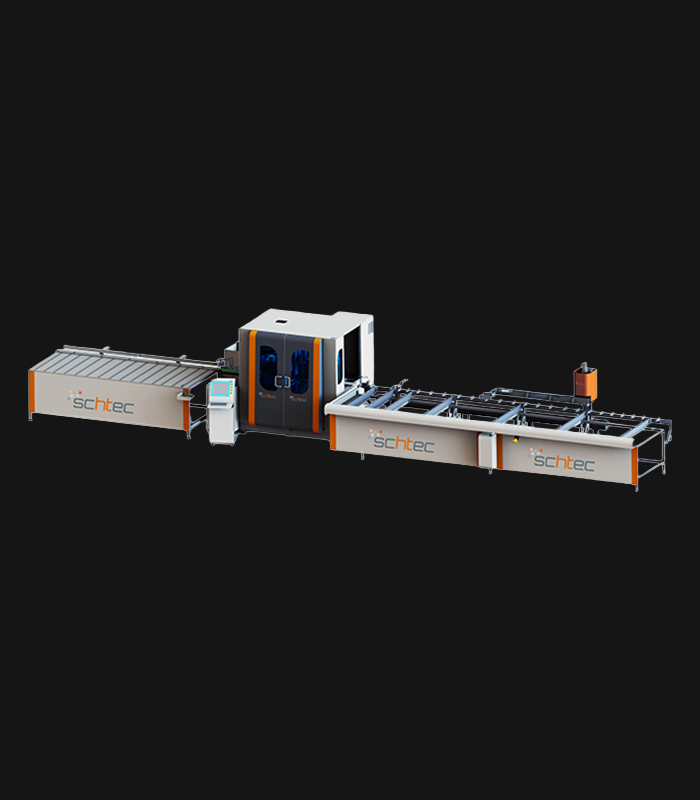

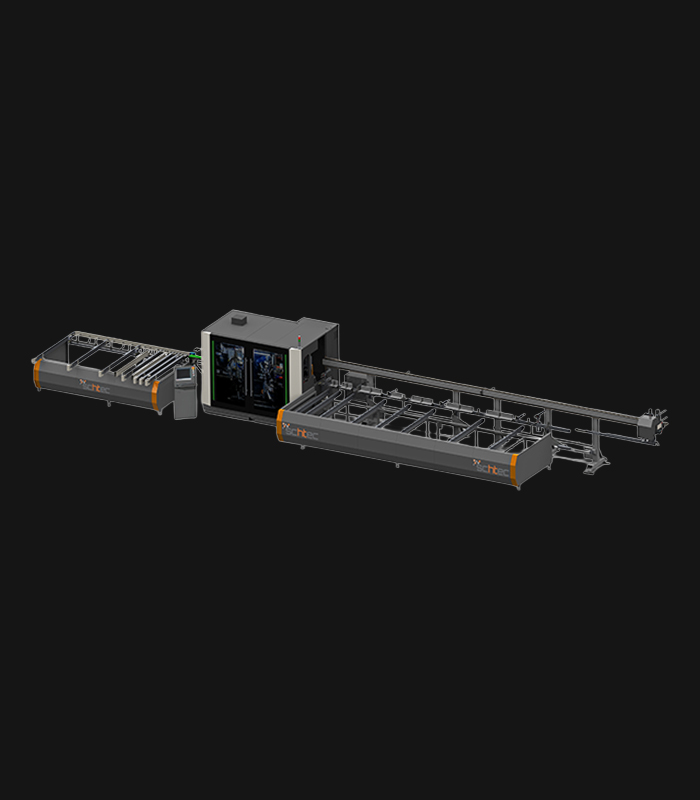

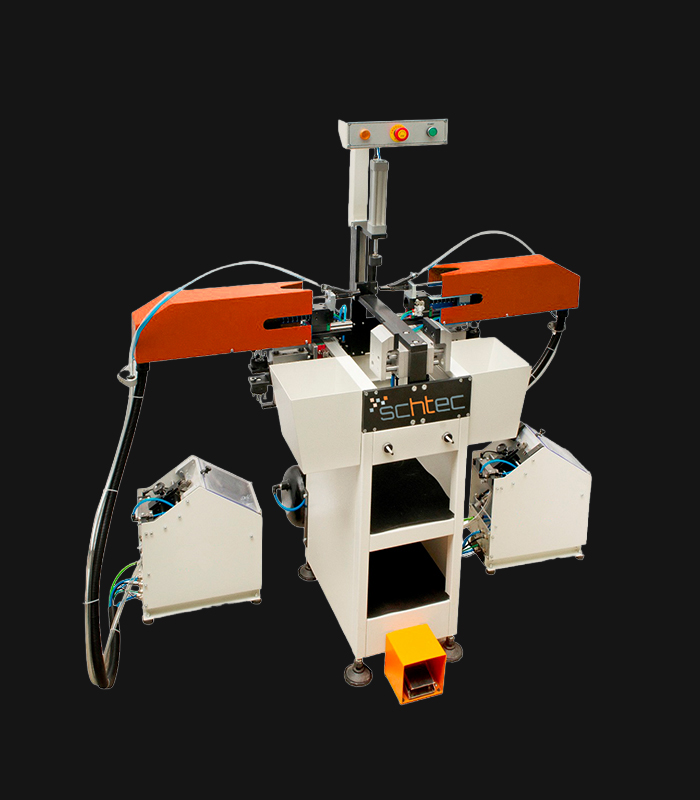

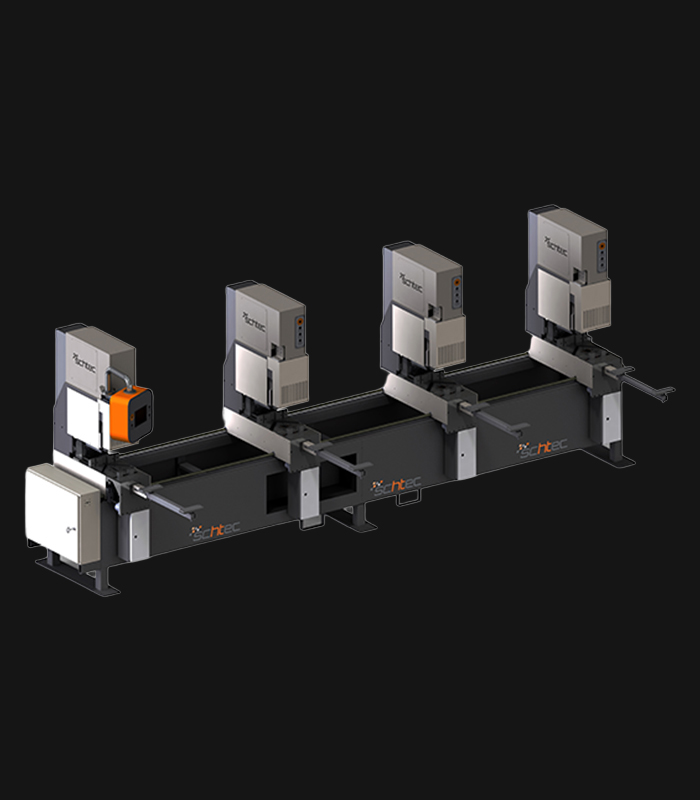

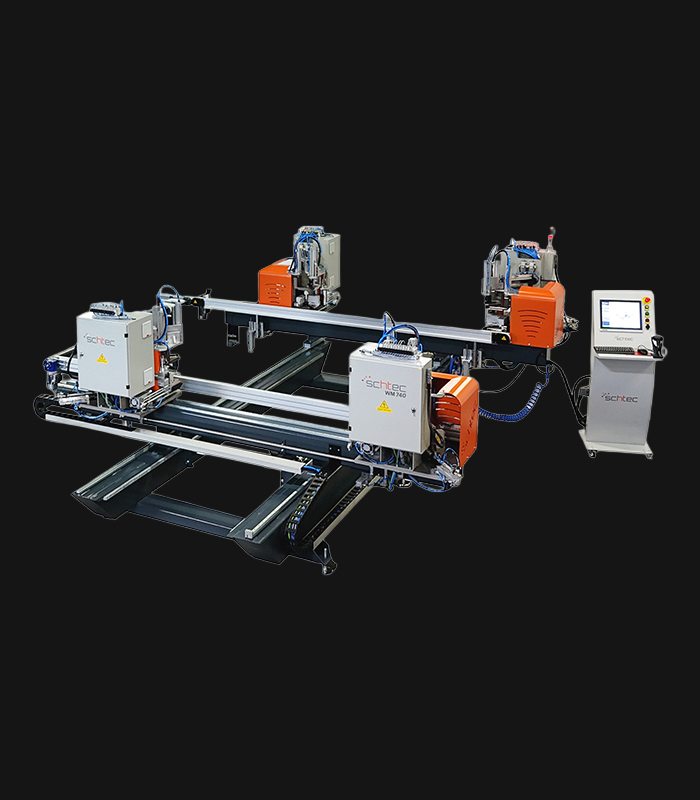

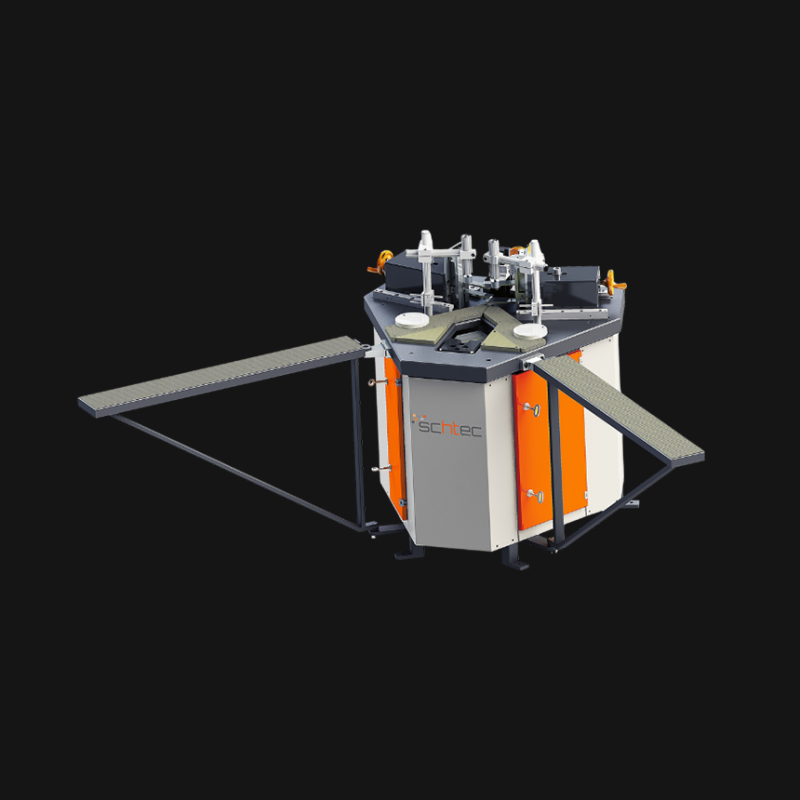

The Power of the 4-Axis Corner Cleaner: The Specialist

A 4-axis machine includes two additional axes of movement, which allow the cleaning tools to tilt and rotate. This capability dramatically expands the range of what the machine can do, transforming it from a workhorse into a versatile specialist.

What It Does: In addition to performing all the functions of a 2-axis machine, a 4-axis model can clean the hard-to-reach inner corners of a welded joint. Crucially, its flexibility allows it to process non-standard shapes, such as arched, angled, or circular frames, and handle profiles with highly complex geometries.

Who It's For: A 4-axis machine is essential for manufacturers producing custom, architectural, or non-rectangular windows. It is also the superior choice for businesses that work with a wide and frequently changing variety of complex profile systems, as it provides the ultimate flexibility to adapt to any job.

Head-to-Head Comparison: Key Differences

| Feature | 2-Axis Machine | 4-Axis Machine |

|---|---|---|

| Flexibility | Standard, rectangular frames | All standard and custom shapes (arched, angled) |

| Cleaning Area | Top, bottom, and outer corners | Top, bottom, outer, and inner corners |

| Ideal Production | High-volume, low-variety | High-variety, custom, or complex profiles |

| Initial Investment | Lower | Higher |

Conclusion: Making the Right Choice for Your Business

The decision between a 2-axis and a 4-axis machine is a strategic one.

Choose a 2-Axis machine if your primary goal is maximizing the speed and efficiency of standard frame production at a more accessible price point.

Choose a 4-Axis machine if you need the versatility to handle custom architectural designs, complex profiles, and require the most complete cleaning process available.

Still unsure which path is right for your factory? The best choice always depends on your unique product mix and growth strategy. Contact the experts at Schtec for a personalized consultation to analyze your needs.